Press Release – March 31, 2016

Global Demand for Industrial Lasers Reaches $3.2 Billion

Fiber Lasers Increase Market Share to 37% – Address New Markets

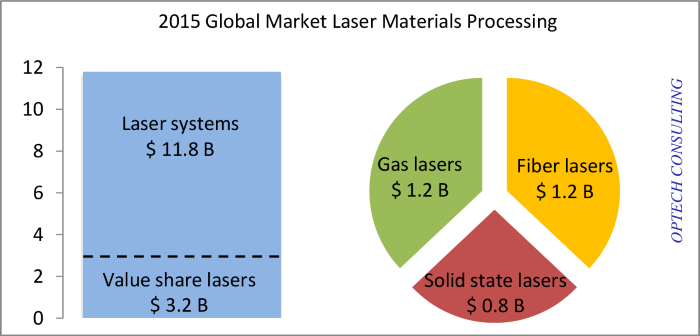

Taegerwilen, Switzerland, March 31, 2016 — The global market for lasers for materials processing reached $3.2 billion (€2.9 billion) in 2015. The market is up from $ 3.15 billion (€2.4 billion) in 2014. The market increased by 2% in US-dollars and by 22% in euros. The difference in the growth rates is due to the euro to US-dollar exchange which increased by 20% in 2015 versus the previous year.

While the laser market increased by 2% in 2015 on a US-dollars basis the laser systems market trended sideward at $11.8 billion. The average value share of a laser in a system increased slightly from 26.5% in 2014 to 27% in 2015. The increase ended a period of several years with markedly decreasing laser prices due to intense competition in the market. The competition was caused by fiber lasers entering established applications of other laser types and aggressive product pricing by new entrants to the fiber laser market.

Fiber lasers for materials processing reached a global market volume of $1.16 billion in 2015, up from $ 940 million in the year before. This puts the share of fiber lasers in materials processing at 37% for 2015, up from about 30% in 2014. Only ten years earlier, in 2005, the market share of fiber lasers in materials processing was a mere 4%. Other solid state lasers accounted for a 26% share of the market in 2015. This includes diode-pumped solid state lasers of various wavelengths, ultrafast solid state lasers, disk lasers, flashlamp-pumped lasers, as well as direct-diode lasers. The gas laser segment, accounting for a 37% share, comprises excimer lasers and CO2 lasers. Excimer lasers are mainly used for microlithography and flat panel display annealing, where they offer parameters not easily available from other laser types. In contrast, CO2 lasers have been a major target for replacement by fiber lasers. This situation is expected to change. While high power CO2 lasers in cutting and welding have already been replaced to a large extent by fiber lasers, low power CO2 lasers are not an easy target for replacement. These are mainly used for non-metal processing applications where their wavelength offers advantages. Also in EUV microlithography CO2 lasers are preferred versus other laser types due to wavelength reasons. Consequently, fiber laser manufacturers now focus their efforts more on competing with solid state and diode lasers. Fiber laser manufacturers also target at new applications such as additive manufacturing, besides pushing sales in cutting and marking by lower laser prices.

For 2016 Optech Consulting expects a sidewards trending global market for industrial lasers. The expectation follows the presently available data indicating a subdued trend of the laser systems market at the beginning of the year combined with weakening demand in China.

Founded in 1992 Switzerland based Optech Consulting specializes in laser and photonics market research and consulting.

For further information please visit www.optech-consulting.com.